5-osiowa frezarka CNC Mira 6S

Obróbka dla jubilerów

Mira 6S – Precyzja i Efektywność w 5-Osiowej Technologii CNC

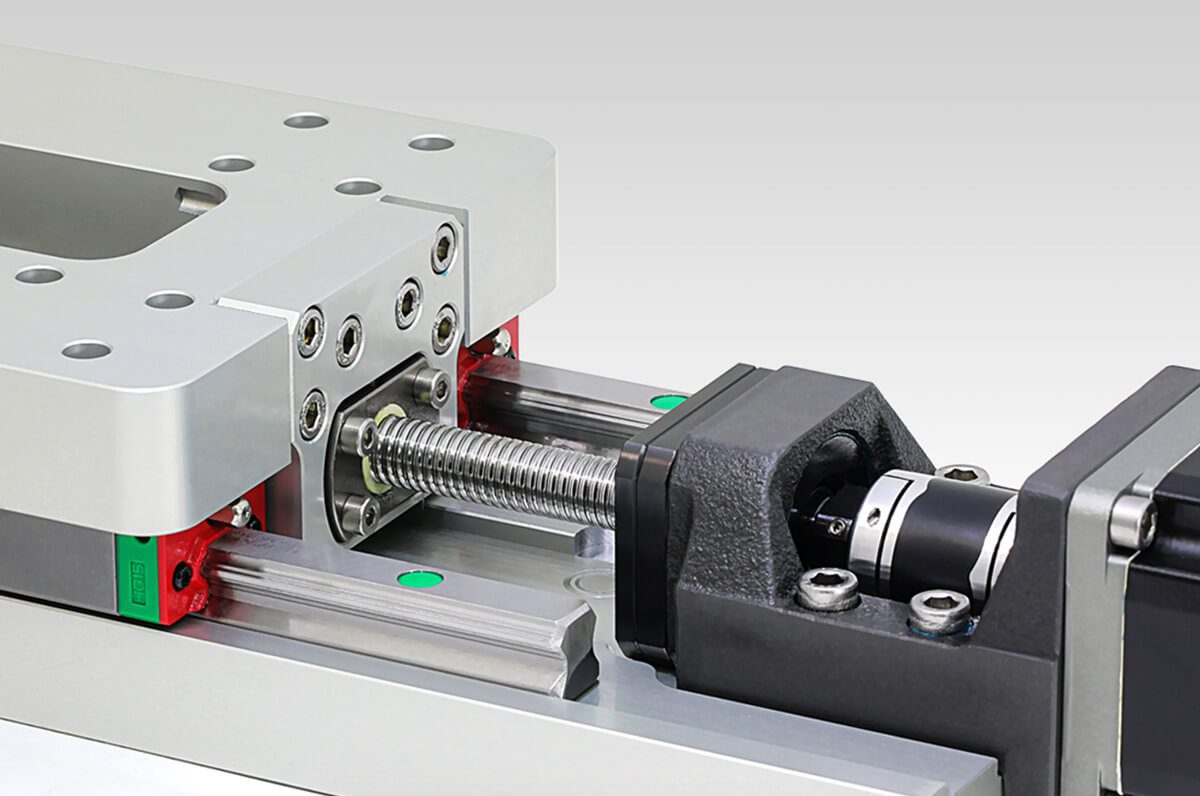

Bazując na wieloletnim doświadczeniu w doskonaleniu technologii frezowania 5-osiowego, Mira 6S łączy najnowsze rozwiązania NS CNC w jednym kompaktowym urządzeniu. Stworzona specjalnie z myślą o branży jubilerskiej, maszyna ta jest jednocześnie niezwykle intuicyjna i wydajna.

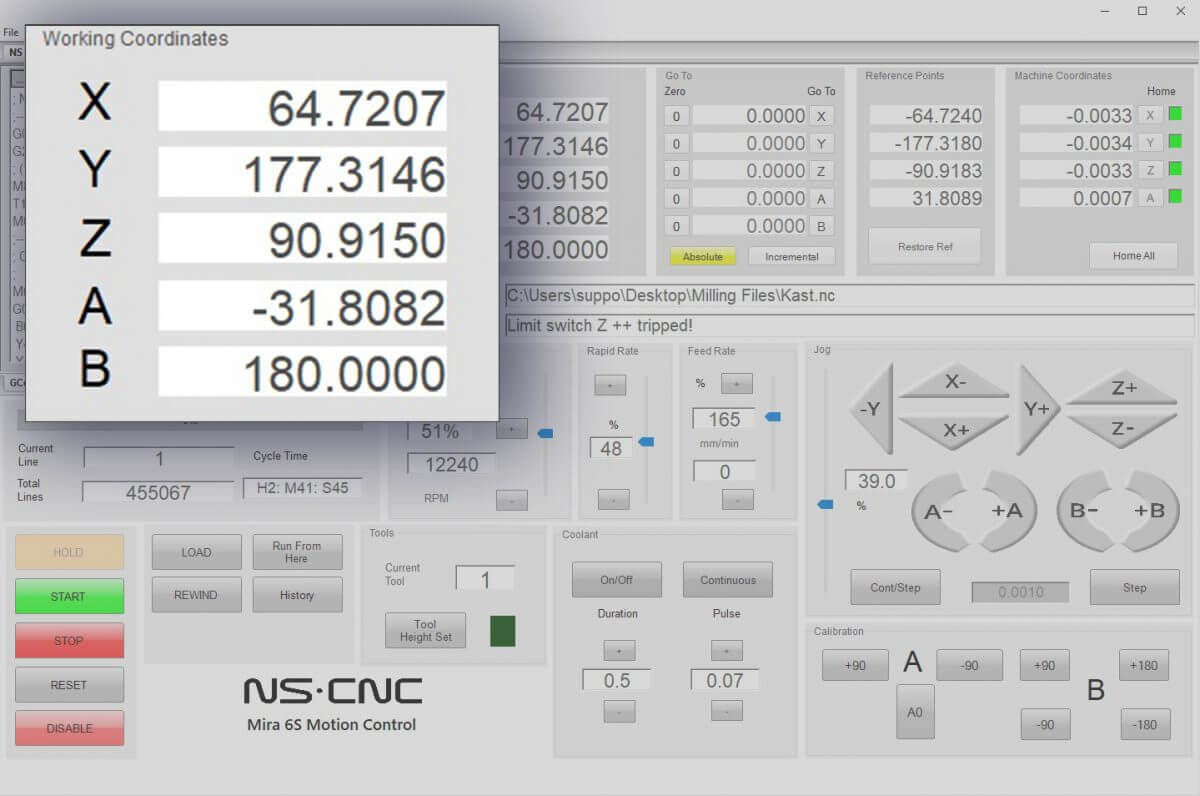

Aby spełnić najwyższe wymagania, Mira 6S została wyposażona w najnowszy system sterowania oraz innowacyjną technologię ‘Smart Rotary Head’, zapewniającą wyjątkową precyzję obróbki.

NS CNC słynie z dbałości o najmniejsze detale, a Mira 6S jest tego doskonałym przykładem.

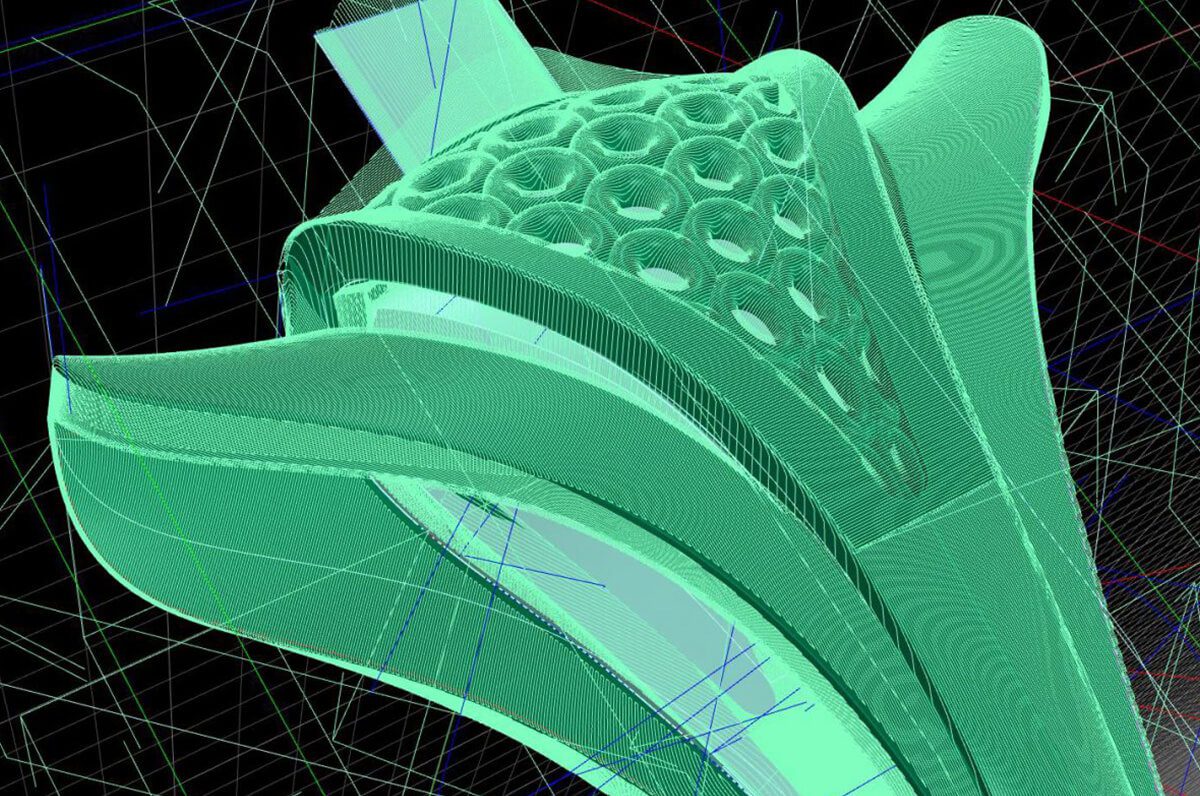

Obserwuj, jak to arcydzieło inżynierii z łatwością rzeźbi nawet najbardziej skomplikowane wzory. Gotowy element można od razu odlać – wymaga jedynie polerowania, co znacząco skraca czas produkcji i zapewnia doskonałą jakość wykończenia.